by Chuck Pierce \ Photos by Rick Carruth

I have been thinking for some time now about adding an asymmetric spinnaker to the sail inventory of my Potter 19. Downwind is her slowest point of sail, but the thought of setting and dousing a spinnaker while singlehanding (sometimes in high winds) has prevented me from building one.

Using the excellent instructions on Judy Blumhorst’s website, I did go ahead and install a bail, halyard, halyard block, and tackline block last year in a moment of confidence. More recently, I was thumbing through Emiliano Marino’s (The Sail Dr.’s)excellent book The Sailmaker’s Apprentice. When I ran across the part where he talks about using two jibs downwind for a more balanced setup than main/jib it set me to thinking.

Why not build a single sail that is shaped like two jibs attached at their respective luffs and sew in a wire down the center with a thimble at each of its ends? Then with a halyard, a tack line and a couple of sheets I could set it flying using the bail and tackline attachment that I had already installed for the asymm.

One advantage over a spinnaker would be that the sheets could be made long enough that if I let them run free, both sides of the sail could luff even going dead downwind. It seemed like it would be much more balanced than main/jib going downwind, and that if I cut it right it might not even need whisker poles to hold each side out.

I floated the idea over on the Duckworks Internet forum, and quickly learned that this had already been done. What I was talking about building was a Ljungstrom jib. The Ljungstrom (pronounced Yung-stroem) rig was designed in the early 1930s by a Swedish guy named, that’s right, Ljungstrom. There is not a lot of information available on it, but I did find a Popular Science article from 1951 that showed the basic rig as a mainsail attached to the aft side of the mast. On the wind both sides fold together to produce a triangular sail shape. Downwind, you open them up and have twice the sail area. I also found information on a boat, So-Do-It (SCA Issue #10), that used a Ljungstrom sail on a stay in front of an “A” frame instead of a mast.

Some of the folks on the forum suggested building an experimental sail out of polytarp, and one of them who has much experience with polytarp sails said that for an experimental one-off, all I really needed to do was tape it together rather than bothering with stitching. He also suggested that I contact David Gray at PolySail for one of the polytarp sail kits they sell, as this would give me a store of supplies and tools containing everything that I would need to make the sail.

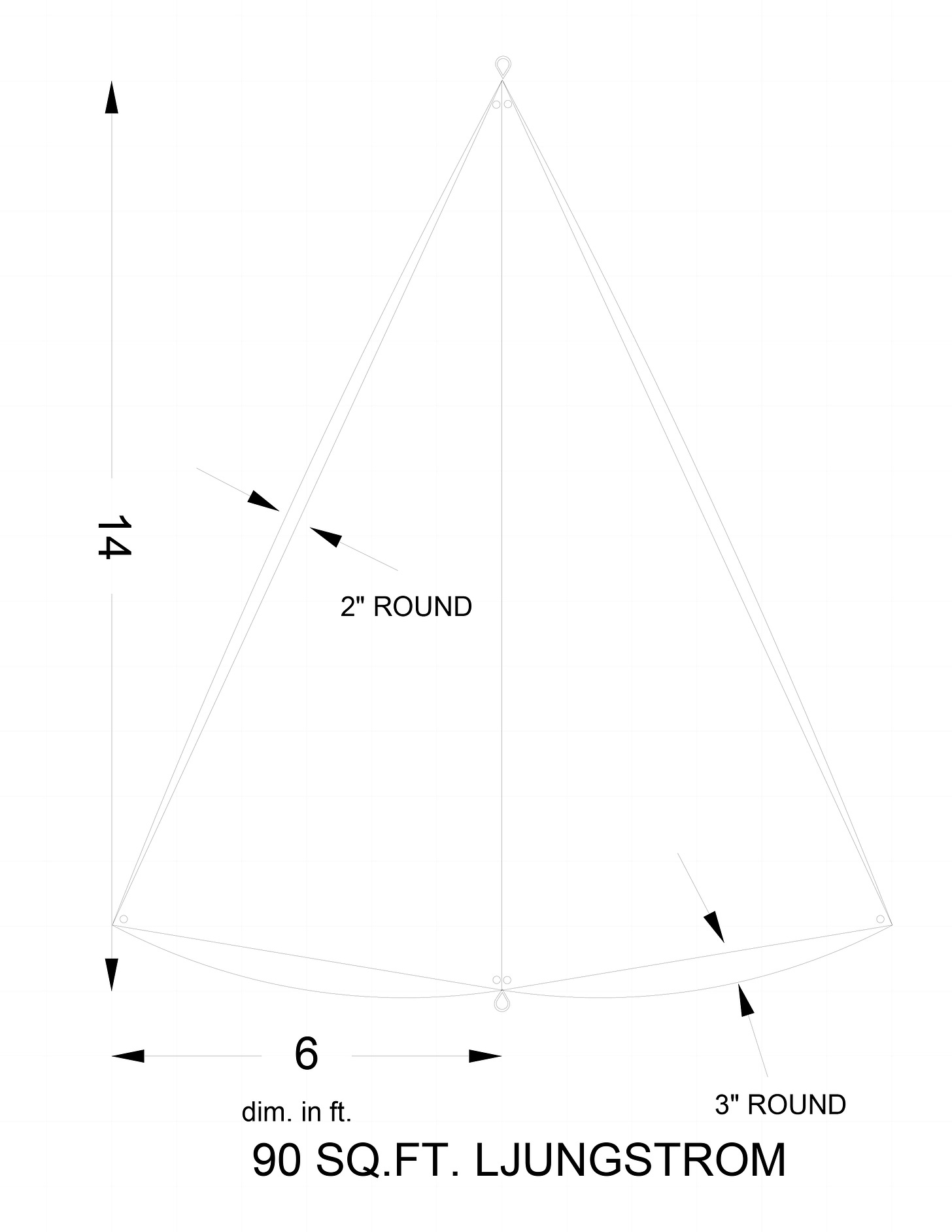

The 2010 Texas 200 was coming up and based on past experience, this would be a good sail to have for that event, so I got out my graph paper pad and started sketching out rough dimensions. I figured that the sail needed to be about 90 square feet for use in the 10-15 knot (and higher) winds that are the norm on the south Texas coast in June. I also looked at a great article at PolySail’s site on making scale model sails out of paper so that you can experiment with their shape before finalizing the dimensions. If you want to design your own sail of any type, check it out; this is an important step that I would encourage you not to skip.

Polysail offers a 12-foot by 20-foot “Sharpie Sail Kit” that includes reinforcing rope, a couple of different kinds of tape, a grommet kit, scissors, and even a measuring tape! Oh yeah, and an 11' 6" by 19' 6" white 6-ounce polyethylene tarp. All this for a mere 80 bucks.

When the kit arrived (in a box that looked much too small to hold all that stuff) I cleared some space in the shop and laid everything out. I checked out Dave’s detailed and easy to follow instructions and had the sail cut out and the supplied rope taped in within the hour. After trimming the rope to length the extra was set aside for later. At that point I cut a 17' length of 7 x 19 1/8" wire rope and put a thimble at each end with a couple of nicopress sleeves. The length of the wire rope from one sleeve to the other needs to match the sail dimensions from the head to the tack, so that just the thimble sticks out over the end of the sail. It’s important to remember that the wire rope goes on the side of the polytarp that will face forward when the sail is set. I added a layer of vinyl tape down the center of the front side of the tarp as an extra protection against chafe, then the wire rope was taped right down the middle of the sail with two overlapping layers of vinyl tape. The sail ended up (from back to front) with polytarp, one layer of vinyl tape, wire rope, and two layers of vinyl tape.

Once the wire was taped in, I got some Duck Tape brand tape (available at Wal-Mart in many designer colors, but I used white) and added the tape as reinforcement at the six grommet locations shown in the diagram above. The grommets were installed through the tape, then some of the rope that was saved earlier was threaded through the top two grommets and the top thimble.

I tied in a square knot, trimmed the ends, and repeated the process for the bottom two grommets and thimble, then melted each knot to itself using a butane lighter, wanting to be certain these knots could never come untied.

On advice from one of my forum friends, I got the rubber mallet out and tapped along all of the taped areas to help set the adhesive on the tape. This makes a huge difference in how the tape holds up over time according to some folks who know much more about this than I do.

I got a hundred feet of 3/8" yacht braid from Chuck Leinweber over at Duckworks for the sheets and cut them with enough length (about 30') that the sail can luff regardless of wind direction, and there is some extra length to accommodate a larger version of the sail as well. At the local hardware store I was able to find three small stainless carabiners that I used to attach the halyard and sheets, then used a slightly larger one to attach the thimble at the tack of the sail directly to the existing attachment point on the bow pulpit. The sheets were run back through the jib blocks and cam cleats for testing purposes.

The following week I was able to test the new sail out on Sabine Lake, a large (seven mile by 16 mile) brackish estuary where the Sabine and Neches rivers converge at the Texas-Louisiana border. After setting the sail up at the bow pulpit and rigging a downhaul through the tack block, I hauled it up for the first time in eight knots of wind. It set easily and worked well with no poles dead downwind and up to about 15 or 20 degrees off dead downwind with a pole on the upwind side. It added a good knot to the boat’s speed over using the main and 110% jib, and the tape held with no issues. The downhaul allowed me to bring it down quickly by myself, then I set the jib and hove to, so that I could go forward and stuff the Ljungstrom in its bag, which I had temporarily tied to the pulpit.

The real test was a month or so later when we headed to South Padre Island, Texas, to meet some friends and sail up to Port Mansfield for the 2010 Texas 200. The sail up to Port Mansfield was great—we had 10-knot winds by about 11 a.m. At one point in our experiments we dropped the main and continued under the Ljungstrom alone making almost 5 knots dead downwind in 10 or 11 knots of wind. The boat did better than normal steering herself in this configuration in spite of the following seas. The winds built to 15 knots by the end of the day, and until the wind went more to the east, the Ljungstrom did well.

I had used the jib blocks and cam cleats with the new sail for testing purposes, but the angle of the sheets was more extreme than it needed to be due to the position of the jib blocks. Also, I wanted separate blocks and cleats for the new sail so that both the jib and the Ljungstrom could stay rigged at all times. After the Texas 200, I mounted a couple of small standing blocks about eight inches aft of the end of the cockpit rail and a couple of cam cleats on the coaming. Now the jibsheets can be left rigged even when flying the Ljungstrom, and the sheeting angle for the new sail is much better.

I have also built a 160 sq ft Ljungstrom for light-air use that has the same basic shape as the original, although it is somewhat wider. It is made of 3.5-ounce tarp material, but even so in very light air both sides will need to be poled out. Other than that they set about the same. The larger sail works well in winds up to eight knots or so, using the same sheets and hardware as the smaller version. At the Sail Oklahoma event last October we made 2.5 knots downwind in 4.5 knots of wind with the larger Ljungstrom set.

A word of caution if you want to try this for yourself: Aldebaran has a backstay, so I don’t worry much about the loads these sails generate on the mast. If you don’t have a backstay on your boat it might be good to install one before you try this.

A word of caution if you want to try this out for yourself: Aldebaran has a backstay, so I don’t worry too much about the loads these sails generate on the mast. If you don’t have a backstay on your boat it might be good to install one before you try this. One more word of caution: I am a hack tinkerer with no formal training in sailboat rigging, sail design, or anything else connected to any type of sailboat. These are experimental sails and what I have written here is my experience with them. They are not suitable for use on anything and in fact will probably destroy your boat the first time you try to use them. When this happens, don’t blame me, ‘cause I told you it would! Build at your own risk.

I plan on using the polytarp sails for a year or two, or until they start falling apart, at which time I will contact our sail guy about doing us a couple in sailcloth with any improvements I (or he) can come up with.

The Ljungstrom jib as a downwind-only sail has proven to be easy to handle, even for a singlehander, and this sail could easily be adapted to any small boat if sized appropriately. I use them for sailing downwind or on a very broad reach, never as a replacement for our furling jib. But for my purposes I haven’t found an easier remedy to the slow downwind performance of the Potter 19. •SCA•

If you are interested in seeing the Ljungstrom in use on the trip, check these videos at the links below.

Judy B’s site: www.blumhorst.com/potterpages

Article on shaping: www.polysail.com/sshaping.htm

Kit instructions: www.polysail.com/article.htm

Videos:

www.youtube.com/watch?v=2ty44tNllPM

www.youtube.com/watch?v=DMUZwPpjQgw

www.youtube.com/watch?v=pKYGDNBoAGo

Chuck Pierce lives in Beaumont, Texas with his wife Kathy and Sadie the half-Lab, half-Golden, Hair Machine and Sailing Dog. He has completed two Texas200s in his Potter 19 Aldebaran.

First appeared in issue #79

Fantastic DIY article, Chuck. This is just what I need to build for my little Potter. And thank you, Josh, for bringing this back out of the archives. It's also great to see that Judy B's link still works! Some really good stuff there.

First thing I thought of when I saw this was that with a Harken dinghy furler and a wire center stay, you could roller reef the sail as well as fully furl it up to make deploying and dousing that much easier…