Ode to the Boat Trailer

The author learns his boat's most important system—the hard way...

Article by by David Nghiem

What’s the most important system of your sailboat? You have 30 seconds to think of it. Is it the lights? Watermaker? Ballast? Sail lines? If you’re a small-boat sailor—the kind that reads Small Craft Advisor magazine—then guess what? It’s none of those. The most important system of your sailboat is the trailer. Yep, that thing with wheels—the very machine that helps you get your sailboat to all points windward at 50 or 60 miles per hour, depending on the highway.

I learned this the hard way last year when my friends and I decided to take my boat out for a fishing trip to Anclote Key, off the Gulf Coast of Florida in February. The idea was we would sail my 20-foot Blockley Privateer Sailboat with all three of us, possibly a dog, with our SUPs and kayaks in tow, to the island. Then we would anchor the mothership and camp on the island, and deploy our smaller craft to fish the surrounding waters. So on a brisk Friday evening in February, my friend Derek came by to get my boat ready to go. My boat was located in the yard behind the bicycle shop I manage, and we were about five miles from the waters edge. The road trip to Anclote Key would be about 20 miles.

We loaded our gear and Derek towed the boat behind his Forerunner, while Joe, me, and his dog, Ritz, drove behind him. We just barely got on one of Tampa’s street’s when I noticed an unusual smell through the car vent. It smelled like burning electrics. Joe noticed it too. We looked at the trailer, which was in front of us, and nothing looked off.

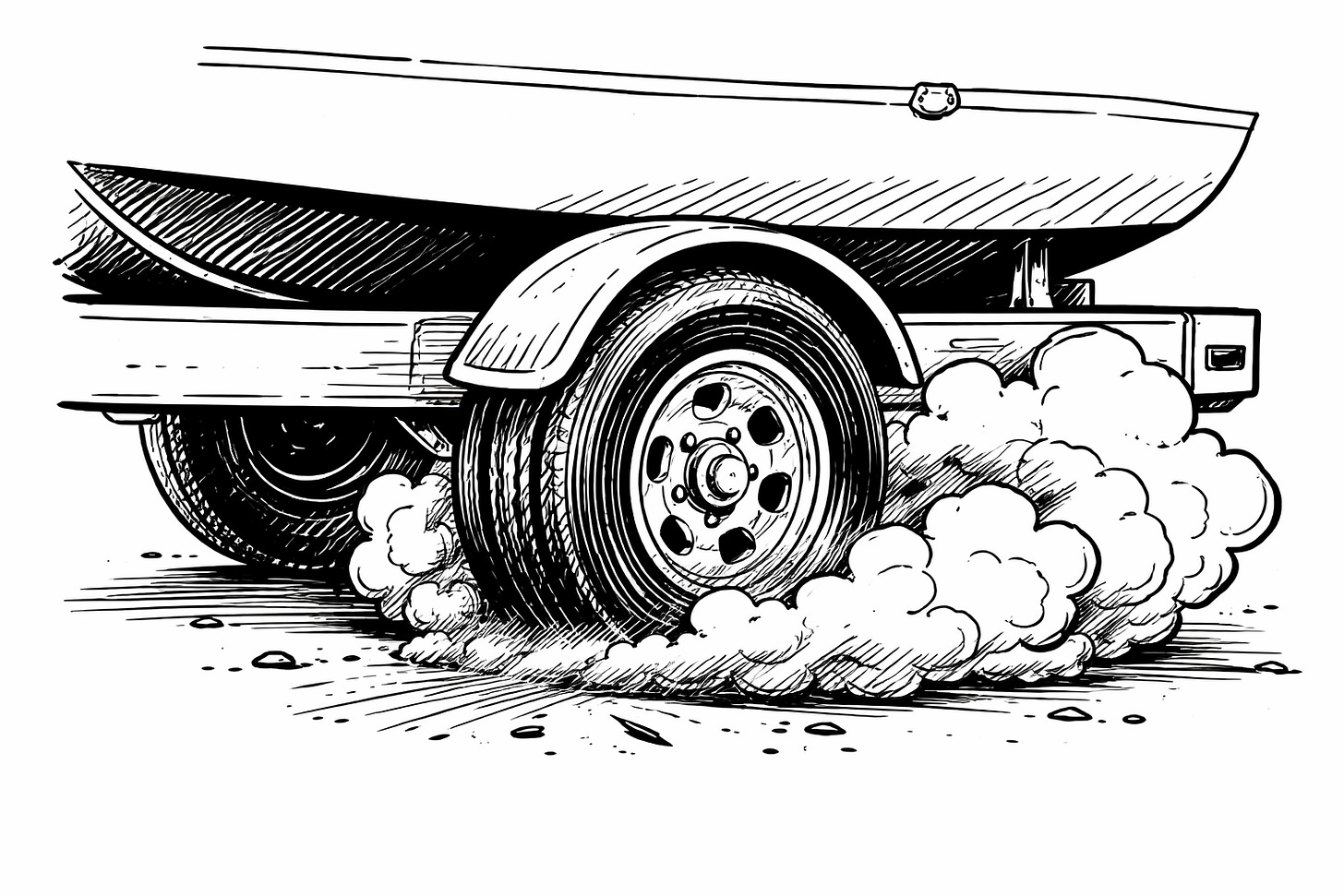

Then we drove on the onramp to the highway and got up to highway speed. The smell was really strong. Suddenly a poof of smoke appeared from the right hand side of the trailer.

“Dude, did you see that?” I asked.

“See what?” Replied Joe in his heavy Chicago accent.

“That! The trailer! I thought I saw smoke.”

“Whaddya mean, smoke? Oh $#!T.” Said Joe as another poof of smoke appeared from the right.

I called Derek to let him know. We pulled off at the nearest offramp, which was just a few hundred feet away, got back into Tampa, and pulled into a gas station. We’d only gone three miles from the shop.

We checked the right side of the trailer. The wheel well was gouging into the tire, which luckily, was a brand new wheel. But it gouged about a 1/2 inch into the tread. We agreed to limp back slowly to the shop, as it was only 1.5 miles away. We went slow, crossing our fingers the entire time hoping the tire wouldn’t explode on the way back. I didn’t have a spare wheel on the trailer.

We managed to get back to the shop without incident. We jacked up the trailer and pulled the wheel off to see what was going on. The axle, which I later learned was a torsion stub axle, had gone bad. The trailer was built before I was born, so it was pre-1976. Given the situation, we decided to get into our vehicles, and head back to Clearwater, across the bay, to find a bar for some food and booze, and to discuss what to do next.

At the bar, after some wings, grouper nuggets, and hard apple cider, we decided to drive an hour north up the coast to a campground, setup camp, deploy our personal watercraft, and fish one of the many spring fed rivers on the Gulf side of Florida. We realized there was no way to get the parts needed that night to fix the trailer, so that would have to be a project for later. Little did I know it would take me almost nine months to get it done.

So I learned a few things about trailers, and in particular, my trailer. We later removed one of the torsion axles to examine it and see if we could order a replacement. That’s where I started running into the problem with using equipment made before modern standards came around. The first thing I discovered was the trailer was custom-built before trailer parts were standardized. None of the old wheels matched modern hubs. Modern axles didn’t fit in the same holes. So I was in a situation where I was essentially engineering a whole new trailer system from scratch.

Let’s start first with the axle selection. There are three common types of small-boat axles on the market. They are the leaf spring type, the torsion axle where the axle length goes from one side to other side, and the torsion stub axle. Leaf spring axles are the cheapest, and simplest of the group, a curved leaf spring or spring pack. The axle itself is mounted at the apex of the curve. The pros of this type is that they’re cheap. The cons are that due to the length of the spring, you need a large area lengthwise to mount both ends, and they’re exposed to the elements, so saltwater will corrode them rapidly.

Next are torsion axles, which use rubber cords arranged around an inner bar housed inside a square tube. When you hit bumps, the inner bar rotates slightly, compressing the solid rubber cords that provide both springing and damping. The pros of this type are that they’re usually well sealed, which keeps out the elements, and they are well suited for saltwater use.

The axle suspension is essentially a solid state element, aka it’s solid rubber that compresses and expands—they last for a really long time. My trailer axles were older than me, which makes that in excess of forty years, and they managed to survive many trips in the Chesapeake Bay, a road trip of over a thousand miles to get my boat from Maryland to Tampa, Florida, and one more sailing trip before they ultimately crapped out. And who knows how much they were used before I bought the boat at an auction in 2022! The cons are they’re much more expensive than the leaf spring.

And then you’ve got my trailer, which uses torsion stub axles. They’re called stubs because of the small length of axle, usually about two or three feet long, and you need one per wheel. It’s built in the same way as the normal torsion axle, except when you mount it, each wheel moves independent of the other axle. This makes them well suited for bumpy or off-road terrain. They’re also lighter and smaller, so their footprint under the trailer is easier to work with. The con is they are substantially more expensive than the normal torsion axle.

It was obvious to me that converting my trailer to the leaf spring axle was out of the question. The trailer wasn’t built for it, and it made no sense to weld or bolt on the extra steel square tubes to mount one. The torsion axle was also out of the question as well, since the ancient brake system (which we actually removed later on) was in the way. That left me with getting replacement torsion stub axles with modern mounts that didn’t match the old holes.

I found a set from a trailer supply outlet based in Delaware. Great, except I was just at the start of the rebuild. Next, I had to get matching hubs. The old hubs didn’t fit any modern axles, and the old wheel mounts were made with an obsolete 4×5-inch bolt patter mount that no one made hubs for, probably since 1990s. Today’s four-hole wheels are four inches. So I picked up a set of matching hubs that were galvanized for saltwater, and a set of matching five-hole mounted, galvanized wheels. Thankfully my one good tire out of the two was transferable to the new wheel. I bought another tire for the other wheel and had a local tire shop mount it.

Then I had to make a trip to the local machine shop to CNC cut some new plate steel to extend the wheel wells out for the new wheel. Despite the measurements I made and the cardboard templates, we still had to grind them out to make adequate clearance space for the tire on the inside edge. Overall, I was out about $600.

Derek came over several times over the next few months once I had all the materials, and we drilled out new holes for the stub axles, mounted them, installed the new hubs, wheels, and tires. We dismantled the ancient brake system, which we discovered when we opened up the ancient stub axle that they never worked. There was no wear area where the brake was supposed to rub. This was definitely a two person job, since we needed to hold parts in place while drilling, grinding, or bolting them on, so we could only work on it when we were both available.

When we mounted the new hubs we discovered that even though they were recommended by the outlet, they didn’t quite fit all the way. After properly seating the bearings and adjusting the preload we could compress the hub into the axle farther and lock it in with the nut. We also found out the hard way that having the boat on the trailer, and working on the ground and trying to fit tools into tiny spaces made for a rough go at trailer work.

Once everything was installed the next step was to re-wire the trailer lights. I found out my one-year-old lights had enough moisture seep-in to corrode the wires, which made it impossible to strip them. I was going to have to replace the trailer wiring as well. Luckily I recently helped my friend convert a late 1990s ambulance into a camper, so we have literally thousands of feet of high quality electrical cable salvaged for the trailer wiring.

Once the trailer wiring is replaced, the next step is to take the trailer out for a short run and to re-check the alignment, before we apply Loctite to the nuts and tighten everything down. Besides that, I also replaced the ancient trailer jack which broke and sparked on the roadtrip from Maryland to Florida, with a shiny new galvanized one that swivels out of the way.

Derek joked that after almost a year working on the trailer I can finally get back to working on the boat. Sailors can be such smart-asses. •SCA•

It seems I spend more time working on the trailers than working on the boats. Tires only last two years and then there is the salt water.., but still better than playing pickleball.

When I took possession of Nereid, I immediately discovered that my original plan of car topping would not work. I ended up going to Hopeless Freight for a trailer kit to adapt as a boat trailer. All went well until I fitted the beam axle to the hubs. I discovered that the axle on one side had been machined to the wrong dimension. After three visits to Hopeless Freight, they insisted on exchanging the entire kit. The new axle fit well to the hubs and I completed the trailer. It tows well and carries Nereid comfortably. Nex step is to get a tongue extender to have less overhang.