Article by Paul Esterle

I recently received a call from a friend, the owner of a Cape Dory 25. He wanted to discuss two related problems and was looking for some possible solutions. Both involved the 31-foot mast on his boat.

The first problem was that he had an antenna cable rigged from the masthead with the coax cable running internally down the mast. With any degree of rolling, the loose wire would slap against the inside of the mast. A seemingly small problem, but one that was driving him (and his marina neighbors) nuts.

The second problem was that he wanted to add a masthead anchor light. One thing bothered me about our conversation on this issue. He stated that his boat was small enough not to require such a light but he felt safer with it. In actuality, his boat, being over 7 meters (23' 9") in length, was required to display an anchor light (anchor light: 360 degree all around view, visibility 2 nautical miles).

The basic wording of the regulation is: “Vessels less than 7 meters are not required to display anchor lights unless anchored in or near a narrow channel, fairway or anchorage or where other vessels normally navigate.”

That’s a pretty loose description of where an anchor light is required so I’d rather be safe, with an anchor light, than sorry without one.

Another often misunderstood ruling is the perception that anchor lights are not required in a designated anchorage. What many people don’t realize is that “Designated Special Anchorage Areas” are so designated by the Secretary of the Department of Homeland Security. Just because the chart states that it is an anchorage area doesn’t mean it is a designated anchorage even if designated by city or state governments. You can find these areas in The Code of Federal Regulations, Title 33 Navigation and Navigable Waters, Part 110, Anchorage Regulations. There in Subpart A, Special Anchorage Areas, are 96 listed locations and their very specific boundaries.

Back to my friend’s problem. He first talked about running the anchor light wiring externally, possibly down a shroud to the deck level. I don’t like the idea of such wiring exposed to chafe, snagging and other damage and recommended that it be run inside the mast. He was going to have to lower the mast in any case, to add the anchor light fixture, so we could address both issues at once.

The first problem was to get the wiring through the mast. I’ve heard of all sorts of solutions for this problem, often requiring dropping a weighted line down the mast to use to pull the wires through with. This only works if the mast is vertical and then you have to go up the mast to accomplish the job. With the mast down, even if inclined, you’re not going the get that weighted line through.

The solution to this problem is something called an electrician’s fish tape. Fish tapes are used to fish electrical wiring through houses, from room to room or floor to floor. They are usually flat metal or plastic tapes about an eighth of an inch wide and about a sixteenth of an inch thick. Common lengths are 50' and 100' more than long enough for our 31' mast. They cost under twenty bucks at a home improvement store but I’d recommend trying to borrow or rent one for the day.

With the mast lying horizontal on sawhorses, the fish tape is stiff enough to be pushed through the mast, Once the fish tape is through, you can use it to either pull the wire through or pull a stronger messenger line through.

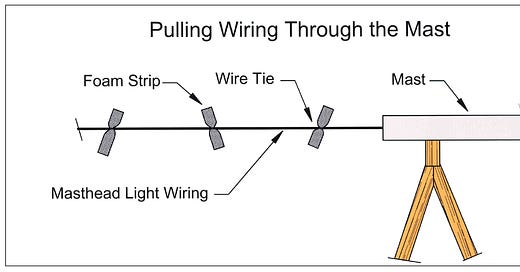

The next step will both pull the new wire through the mast and solve the antenna slapping problem. You will need to locate a supply of soft, flexible foam. One source would be from electronics packaging, the black foam that many components are shipped in. Another source would be upholstery foam. You are looking for soft, flexible foam, not hard, rigid foam.

Cut the foam into strips. Depending on the dimensions of the inside of the mast, in the range of 3" wide and 6-8" long. Fasten these foam piece to the new wiring about every two feet or so with plastic wire ties. They do need to be well enough fastened so that they don’t slip when pulled through the mast. The size of the foam pieces should be so that as the foam is pulled into the mast they fold in half and fill the interior of the mast but not so much that the pulling is difficult.

Once all the foam is attached to the new wiring, you can proceed with the pulling. This will require one person at each end of the mast. One will be pulling the fish tape or messenger line, while the other guides the wire and foam into the mast opening. The foam will prevent the new wire from slapping against the mast and will also trap the existing antenna cable and keep it from slapping.

Once the wire is through the mast, you can proceed with installing the new anchor light. Here you will have some choices. Typically, the anchor light has an incandescent light bulb. Recently, several manufacturers have developed LED lights that meet the Coast Guard requirements. An individual LED bulb doesn’t have the light output of an incandescent bulb, so LED lights are usually an assembly of multiple individual LED bulbs. LED’s will use from about a half to a tenth of the power of an incandescent bulb and has a much longer life span, an important consideration when changing a bulb means climbing the mast or lowering it. On the downside, LED’s have a higher initial purchase price.

A quick glance in a popular marine catalog pointed out just how big a difference in price there is. The cheapest LED anchor light assembly I could find was about $215. On the other hand, a typical incandescent bulb style masthead assembly was around $70, quite a disparity.

In terms of power consumption, looking at the catalog specs, the incandescent bulb draws .42 amps while the LED draws .2 amps. Over a 12-hour spell, the old style bulb would consume 5.04 amp hours while the LED will only use 2.4 amp hours. That equates to being able to run your LED anchor light more than twice as long as the incandescent type.

By way of illustration, a group 24 marine battery has about 65 amp hours of capacity, full charge to full discharge. However, flooded cell batteries should not be discharged below 50%, leaving about 33 amp hours. But flooded cell batteries are seldom fully charged, usually remaining about 85% charge, resulting in about 23 useable amp hours of power. So you could run your LED anchor light for about nine days compared to the four days for the incandescent style.

One thing I need to mention is the type of wire to use. It should be marine grade tinned wire. I would suggest using duplex wire, i.e. two insulated conductors inside an insulated sheath, much easier than trying to pull two separate conductors through the mast. Most marine catalogs and web sites will have tables that help you in determining the correct wire size for the length of wire needed. Don’t try to use smaller than recommended wire as it will drain the battery even faster.

For example, calculating the length of wire at 32' for the mast and another 8 feet for connection inside the boat gives a length of 40 feet. However, the length is to the light and back, giving a total length of 80'.

Looking at the 3% voltage drop table in the West Marine catalog, I find that #10 wire should be used. Two conductor 10 gauge duplex safety wire is listed at $1.63/ft. for a total cost of around $65. Not exactly cheap but it is a job you only want to do once.

The other requirement will be some means of getting the wiring from the bottom of the mast to the inside of the boat. Here I suggest the use of a Blue Seas System CableClam. This unit will provide an easily installed, waterproof through-deck fitting.

One additional safety thought. When I had Ternabout on a lake in Tennessee, I always hung an additional light from the boom. The lake I was on was a very popular fishing lake and we always heard bass boats out after dark. I was never convinced that the guy screaming down the lake at 2 a.m. in his 115 hp, 16' bass boat would ever be looking up for anchor lights, hence the cockpit light. It worked for all those years. •SCA•

First appeared in issue #76

Instead of foam I used zipties snugged tight around the wire which seemed to do the job.

I also prefer the zip tie solution—easy to do and I worry about foam trapping moisture against the aluminum mast. (Perhaps a sign of OCD?)

If you are using an electrician’s fish tape, be sure to tighten any internal halliards out of the way so they don’t get twisted in with the wires. Also, leave a messenger in the mast when you are done for next time .

If the mast is up, the time-honored bicycle chain weight worked for me.