Article by Joshua Wheeler

The windowpane seals and gaskets on the opening portlights of Sampaguita, my 1985 Pacific Seacraft Flicka 20, showed age. A few were seeping around the panes. At first, it was daunting to consider taking these oval bronze portlights apart. They keep the Pacific Northwest rains out of the boat. However, a stitch in time saves nine.

My research did not uncover precise how-to instructions but helped narrow my options. Pacific Seacraft has a service to rebuild them at around $335 each, plus shipping and tax. With their expertise, I suspect (hope) they do an outstanding job. Or, I could take a chance on myself, order supplies for around $150 to refit all six, invest the sweat equity, and learn something in the process. Since you are reading this, you know I chose the latter. In my case, the seals between the frames and the cabin top were still good, so this focuses only on the opening hinged portlights. It was a discovery process, and I was uncertain what I would find, so I removed and rebuilt one portlight at a time.

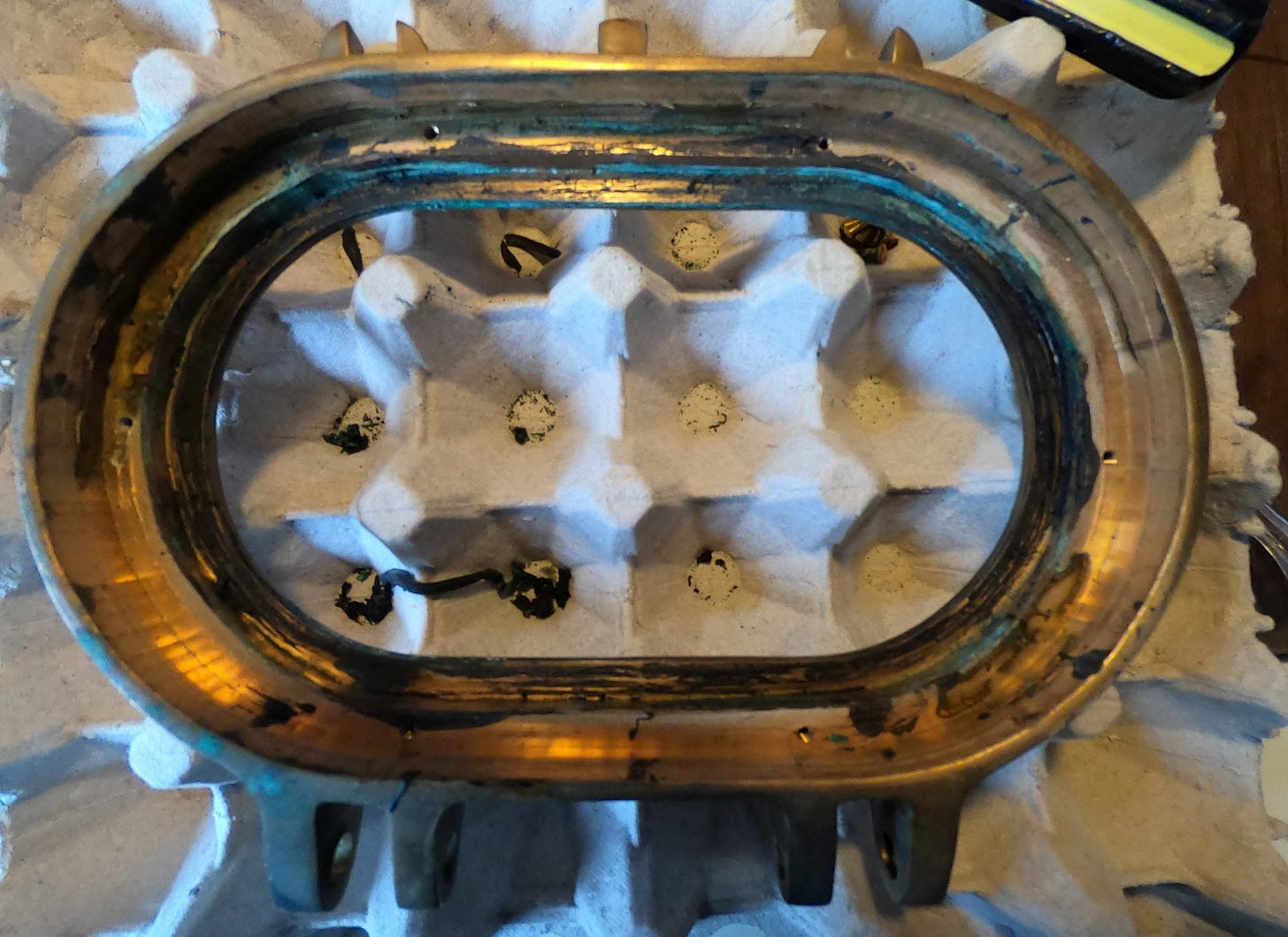

Detaching them from the frames was intuitive and fast. I then placed the portlight on my workspace, outer gasket, up. This gasket formed the watertight seal with the frame and required removal to access the pane inside. It also destroyed it.

Under the gasket, I found six to eight (depending on portlight size) brass screws that held a retaining ring in place. These screws were 4-32x1/4" or 4-32x3/8". I found a mix, though the 3/8" rarely fit well. I removed these. A bedding compound was used under the retainer to seal the windowpane in the portlight. My rings and panes either popped right out, required prying, or a fine blade to break the seal.

With the pane removed, I used acetone, a box knife, a razor blade, a screwdriver, sandpaper, time, and elbow grease to clean all the surfaces.

I chose a black silicone-polyurethane hybrid for the new sealant, banking on compression more than adhesion to seal the panes. I liberally added this to the panes frame, gently laid the glass in, added more on top, filling in any spaces, and put the retaining ring in place. Using new 1/4" brass screws, unless 3/8" fit properly, I started their threading, careful not to squeeze out all the sealant, leaving room to tighten them later. I let this cure for at least 24 hours, then drove in all the screws and trimmed away the excess on both sides of the pane.

Unable to source outer gaskets, I did find 3/8" square silicone rubber bar stock. I cut it to fit the retaining ring, using a jig to trim the ends at 45-degree angles, creating a scarf joint for a better seal. Using the same hybrid sealant, I bedded the ring, focusing on the bottom and inside edge, then laid the rubber bar in, sealing in the scarf joint on the top of the portlight.

I immediately reinstalled the porthole in the frame, using the Allen wrench adjustments to ensure a square fit and compression. I used rags to clean any sealant that squeezed out on both sides and let it cure. After a few days, I used pressurized water to test the seals. I was fortunate enough not to have any leakers.

If you take on this project, there are some aesthetics to consider. Sampaguita appears to have the original two-pane safety glass windows. Mine had some cloudiness around the edges from moisture ingress. I researched replacing these with new glass or acrylic but ultimately decided to reuse the old ones. Next, if you like bright and shiny, the bronze frames and portholes could be polished more easily when disassembled. Also, the silicone bar stock offered by my source came only in red. Black may be available from a different vendor.

Like most boat projects, expect complications. If your panes have been leaking for a while, the brass screws holding the retaining ring may have dezincified. Of my six portholes, two panes had this issue with the lowest two screws. Three out of four, the heads came off, but I used penetrating oil and pliers to remove the shafts. The fourth was more of a production as it broke off inside the frame and required me to drill it out and later re-tap the hole to a 5-40 size. The larger screw also meant some machining to the retaining ring and the screw itself to ensure a good fit. That one fastener was the most complicated part of the whole job. Also, the tedious chore of cleaning the surfaces will depend on the sealing compounds used previously. Mine had a couple of different materials and tenacities.

As a sailor and not a professional shipwright, I am not an authority on how best to repair these portlights. I felt capable of doing the job, and it was apparent the savings on labor would be significant. As with many things, the fear of the unknown is often the biggest block. I'm hoping this will remove some of the mystery of the job for those courageous enough to give it a go. For boaters who want to have big adventures with small budgets, The Resourceful Sailor presents insight into how that might be possible. Remember, keep your solutions prudent and safe, and have a blast. •SCA•

This installment of The Resourceful Sailor first appeared in ‘Lectronic Latitude on Jan. 18, 2021.

A nice job refurbishing the original high quality portlights. I rebedded the portlights on my ComPac Catboat last year. It was a much more daunting project given the lower quality plastic portlights and a failure prone original installation.

I owned a Pacific Seacraft 31. It was a 1989 model with rectangular bronze opening ports. I read that they switched to rectangular ports because of leak issues with the oval ports.