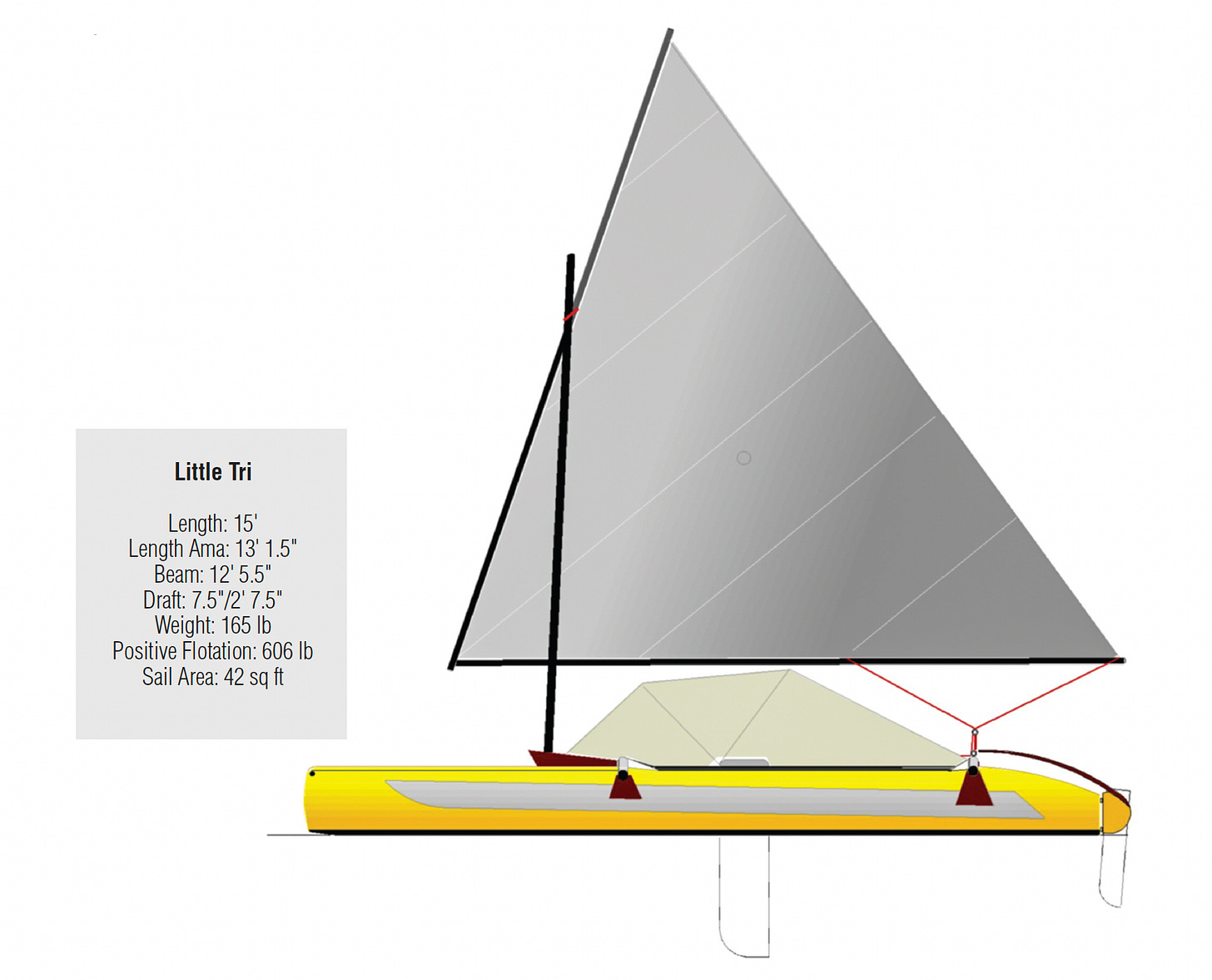

Little Tri

Article by by Bernd Kohler

Being boat-less for some years, I decided it was time for that to change. I have designed monomarans, catamarans—why not for a change a trimaran? I am fascinated by the double outrigger boats from the Philippines, the Bangas and the double outrigger boats from Indonesia, the so-called Pirouges. These are seaworthy, fast and look very elegant in my view. They normally use big bamboo pieces as amas, a material difficult to get anywhere but in Asia for reasonable costs. But we have a cheap substitute, namely PVC tubes. And the idea for my double outrigger boat was born.

The main requirements were, keep costs if possible at not more than US $ 1000, for all material and rig. There is not much material needed. For the whole boat including rudder and dagger board you need 4 sheets of 4mm plywood, 2 sheets 8mm plywood, 30 m fir, 8 kg epoxy and 12 m2 glass cloth. Construction time runs around 120 hours. A tight budget and not much time. Sharpie hulls are the easiest to build, of course in the plywood/glass epoxy composite system. Akas (crossbeams) are clear aluminum tubes and amas (outriggers) the ubiquitous irrigation PVC tubes with a diameter of 160 mm. For the sails and rig the Sunfish rig was the logical choice.

Sketching around a bit and calculating, an outrigger boat with high aspect ratio sharpie hull came out—Little Tri.

The PVC amas have, through the restriction of the diameter only a volume of about 82 kg (180 lb) so hiking out in above wind force 5 is necessary. No problem—the trampoline/seats are a perfect place to do so. I mount the trampoline material loose enough that it forms a comfortable seat. In this way the strain on the trampoline connection points is lower than with a stretched trampoline. All aka connections are done with ropes as is also usual on Pacific outriggers. Clasps with ropes can be used as well.

The hull is a high aspect ratio sharpie. Its straight sides are easy and fast to build. Construction is of plywood/glass/epoxy composite as with all my designs. The self draining cockpit is 2 m long and the minimum width at the cockpit floor is 0,5 m. With an awning over the boom it makes a snug and protected space for one person to sleep.

On the complete Sunfish rig I used a carbon windsurf mast because they are cheap here in France. For good windward work I chose a daggerboard. The daggerboard case is outside the hull—so no chance to damage the hull if an obstacle is hit hard. The case has a trapezoidal shape. By canting the daggerboard forward or backwards, the center of lateral resistance can be changed for best sailing performance.

Construction is the well known and easy to learn wood, glass, epoxy composite system. I use a construction system known in aircraft construction as matched hole technique. Where accurately made aluminum parts are assembled with clecos (temporary aircraft rivets). By placing wood screws instead clecos at strategic places to form triangular strong points, the hull is pre mounted. Next the wood screws are partly removed and epoxy glue is applied and the screws tightened again to the old screw holes. No hassle here or searching for marks. After the epoxy is cured, remove the screws and there is the hull.

Rudder and daggerboard have a very good profile and are easy to make with my time proven construction system. They are mainly made from 4 mm plywood and some strands of uni-directional carbon fiber.

Before you ask, PVC has to be specially prepared so that the aka holders can be mounted. This is all clearly described in the construction manual that comes with the drawing set.

The drawing set and plans are available for US $76.00 at Duckworks. •SCA•

First appeared in issue #95

I like several of the features of this trimaran. I like the fact that the centerboard is offset so that there is no hole in the hull to invite wood rot. On my Bolger designed Birdwatcher the offset mast and offset centerboard were never an issue. I am also a fan of using lashings to secure the cross arms. On my Birdwatcher, I also lashed the mast in place with 12” line.

Jim Michalak built a Birdwatcher at about the same time and questioned whether this arrangement was strong enough. He sailed with me and sat next to the mast to watch it in operation. Unintentionally, we had a brief knockdown and, as a result, he decided that this arrangement was in fact sound.

However, I have some concerns, and perhaps the designer can enlighten me on these. I have owned three trimarans: two Windriders and a Hobie OutIsland. All three have relatively short amas, but in light winds, it can still be difficult to tack. These amas seem to be exceptionally long, so is tacking an issue? I know Polynesian bamboo amas are long but I believe they were making mostly extended straight line voyages rather than trying to tack in restricted areas which is sometimes an issue on inland lakes.

Another issue is the trampoline which significantly hinders paddling during launch and recover. The OutIsland could be rolled up out of the way. Is there some way to disengage one corner of the trampoline for paddling?

Thanks to publish this article again. The design is a big success. Logical, to build the boat it is comparable to a mono hull plus some work on the PVC tube amas. About 20 hours. It is fun to sail for beginners as seasoned sailors. Lateen sails (Sunfish sail is just that) have a low center of effort compared to sloop sails with the same sail area which makes the boat more stable. The boat is anything but sluggish. Watch this video from a client.

https://www.youtube.com/watch?v=ENi2rWtJqu8