Let’s Design the Perfect Little Boatshop

…So We Can Work on a 20’ (or Shorter) Small Craft

Small Craft Advisor readers are passionate about boating, of course, but there might be one thing they love even more: Working on small boats. You folks do it in your garage, your carport, or under your Costco shelter if necessary.

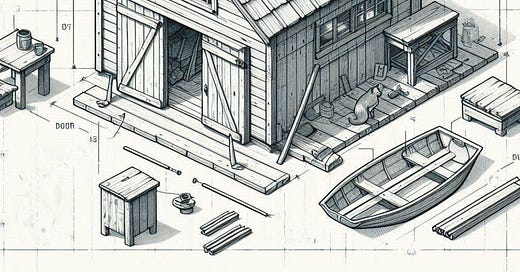

That’s well and good, but what many of you want—really want—is an actual-factual boatshop. Nothing that’s “Make-Do.” You want a space that’s tailormade for working on your current small boat, or building the next one…a shop that’s designed for the purpose, not overly large or expensive. Maybe just enough space, and the right kind, to accommodate a boat that’s up to about 20 feet in length.

Okay, let’s design a Perfect Little Boatshop together, starting here and now.

Personal aside: I’m retired so I should know better, but I spend 200 days each year working on boats, but only 40 days actually cruising. For someone who loves to be on the water, that’s a crazy ratio. You’re smarter than me, maybe on many levels, but I’m guessing many of you share my passion for shop work and you never quite find enough time for boating. Many of you’d like to have your own personal shop in the backyard, or somewhere close to home, so we share the same disease. If admitting our addiction is half the battle, let’s figure out how to build our own little shop, alone or maybe in partnership with friends. But let’s do this thing!

…And here’s the carrot: Our buddy Josh Colvin, editor of Small Craft Advisor, got in touch wearing his other hat—proprietor of Glen-L Marine Designs, the source of boat plans and kits since, well, forever. Inspired by the fact that Glen-L already offers architect-designed plans for tiny houses and vacation cabins, Josh said he’d like to develop building plans and instructions for a small boatshop—something customers might build in their backyard, or anywhere they desire.

So, your assignment is to think about the space needed for a small boat you might build or restore in your dream shop. What are overall dimensions—length, width, interior height? What about roof design, doors both large and small, lighting, heat and/or air conditioning, and maybe room to flip a hull during construction? How much floor space might you need for stationary tools along with work benches, hand tools, storage for paint, varnish and epoxy products, and the always-appreciated cubbyholing of keen junk, meaning old boat hardware, tools we rarely use but can’t be without, along with lumber, sheets of plywood and other important items?

With a big budget—(not happening!)—we could go nuts on this assignment, but a key goal is to keep the shop easy to build and relatively affordable. In other words, maybe achievable for ordinary folks.

So, to get the ball rolling, I’ll describe needs and specifications for what could be my own Perfect Little Boatshop. Those of you who have thoughts on design of your own ideal shop are asked to describe what you’d like in the Comments section below. In addition, please consider submitting your design ideas, drawings or what-have-you to me, Marty Loken, at norseboater22@gmail.com (We’ll celebrate some of your shop ideas in the next Shallow Draft column.)

Marty’s Perfect Little Boatshop

The small shop of my dreams won’t be built in the near future, since I’m happily finishing my current project, the 20-foot cabin cruiser TATOOSH, in a building shared with friends. After I launch TATOOSH next Spring—the project we’ve been describing in a series of Shallow Draft columns—my future focus will be on restoration of skiffs and sailboats in the 14- to 16-foot range, starting with an 1870-design melonseed in need of major work, followed by other small rowing boats and tenders. So my future shop needs will be less demanding than other spaces I’ve been lucky enough to occupy.

Stationary tools I’d like to bring to a new shop: Old cast-iron contractor table saw, 14-inch bandsaw, floor-stand drill press, 14-inch surface planer, and tool-triggered vacuum with 6-inch random-orbit sander and 3” x 5” finish sander.

Portable tools include a collection of hand planes, battery and corded drill motors, Japanese back saws, sanding blocks with various grits of paper, screwdrivers, chisels, mallets and hammers, pry bars, metal files and wood rasps, and a skinny metal shelving unit holding bronze wood screws, bolts, rivets and roves, and ring-shank nails.

I have four 3-foot wide, 6-foot tall metal shelving units—two for paints, varnishes, thinners and such, and one each for epoxy products and miscellaneous cleaners, polishing compounds, oils, wire brushes, extra tools, etc. (If moving into the shop we’re designing here on paper, I’d reduce the four shelving units to two.)

A bonus I’ve enjoyed in larger shops, and I’d like to imagine fitting into this one would be wall-mounted steel-arm racks: One for lumber (six arms) and one for spars I might use someday: Masts, booms, yards, gaffs, sprit poles, and the like. I could cut those in half, too.

Another category is storage for sheets and partial sheets of plywood. (I find it almost impossible to part with even the smallest leftover scraps of marine plywood, since we never know when we might use that weird, triangular piece of 6mm Okoume. So my solution is to push whole sheets and partial bits up against an open section of wall, quickly losing track of the small fragments I thought I’d never live without. (Right now I have about 15 whole sheets of plywood and the equivalent of 6 more in small fragments. The number will plummet as I get deeper into the TATOOSH project.)

There are three other important ingredients in my dream shop: 1) Work benches with woodworking vises; (2), Rolling metal carts to move certain tools or other items close to the current project, and of course 3) Clamps, clamps, and more clamps, because as the truism goes, “You can never have enough”. (At the moment one tall metal cabinet barely contains my smaller wood clamps. Longer ones, used less often, are clamped onto overhead shop frames.)

Actual Shop Dimensions…

My dreamed-about boatshop would be built with a footprint that’s 28 feet long and 20 feet wide, with a 12/8 pitch metal roof, and trusses that are 12 feet over the shop floor. Attached to some of the trusses, when needed, would be four 1,000-lb-capacity chain hoists with 2-inch wide yellow nylon straps, to lift small boats and occasionally turn them over.

Outside walls would be framed in 2’ x 6’ fir and overall shop dimensions would suggest use of a lot of 4’ x 8’ sheets of exterior plywood. Walls and roof would be properly insulated, power would mainly be 110v, with 220v for one or maybe two overhead electric heater fans), and in a perfect world there would be some storage in the rafters for boxes of keen junk that I rarely access but can’t part with. While mentioning heaters, some of you might prefer a shop wood stove…producing heat while helping get rid of wood scraps. I’ve done that, too, and also worked in shops with no heat…just adding layers of clothing as needed. But if you live in a colder climate than we experience here in the Northwest, you’ll want a serious heating source.

We don’t need air conditioning in our corner of the world, but an overhead air scrubber might be nice, and natural light through windows and skylights would be a bonus.

The 20-foot end wall would feature a large 11’-high x 12’-wide barn door, with windows in the upper portion. We’d want a standard man door somewhere else, and up to six other windows—three on each side wall, placed with their bases 6 or 7 feet above the floor and spaced to allow room in one spot for 4 x 8 sheets of plywood stacked on end. With windows kept high on the side walls, we’d be able to place the tall storage units most anywhere, without blocking natural light from the windows.

Speaking of windows, it would be nice if one of the side windows was 6 feet wide and at a lower elevation, behind and just above my 6-foot-long workbench. (Always great to have natural light there.)

So, there’s only one other thing on my shopping list, and it could be added at a later date: A shed roof hanging off one side of the building, to protect a rack of boatbuilding lumber and spars—nice to store outside of the main shop space. And as a bonus, the shed would be about 12 feet wide, to shelter our small boat when finished, or between repair sessions.

I’m forgetting several things, but this is where you take over. In the Comments section below, please describe the Perfect Little Boatshop of your dreams (in whatever detail you wish), and if you want to illustrate the building or its components with drawings or what-have-you, please email them to me at norseboater22@gmail.com (As mentioned, we’ll spotlight your ideas in the next Shallow Draft column.)

Thanks, as always, for reading. - Marty

Lets see - a wood floor. As much natural light as possible, and, since I am in the Pacific Northwest, sufficient electrical light for older eyes - which means a lot of light. Heat for three seasons! If generating any kind of sawdust, a dust collection system, with the machinery and collectors outside the shop, under a small shed roof (such a system has made a huge and very positive difference in my brothers shop). Overhead electrical outlets, preferably on reels. I'd be tempted to build the back wall of the shop so that a longer boat could on occasion be accommodated. Long workbenches on each side of the shop that could support planking jigs and longer masts and/ or spars.

One of the issues I mind when laying out my workshop, is that we boat builders often handle long lengths of lumber, stringers, planks, mast staves and such all go over the sawbench and, or through the thickness planer so I make sure that I can do that without obstruction. In one small shop I occupied for a while I made a "hatch" in one wall which lined up with those machines on the outfeed side, so, with the hatch open I only had to accommodate the infeed end within the shop.

In others I line those machines up with a doorway, and in my current shop which is 12 meters long I have lined them up along the boat build space which is on one side along the long axis of the shop.

The bandsaw is also a consideration, mine being a 20 in heavyweight unit there are times when I'm putting really big pieces of plywood through that, and I need space in which to swing up to half a sheet when cutting curves so the location of that, with enough clear space in which to work is essential.