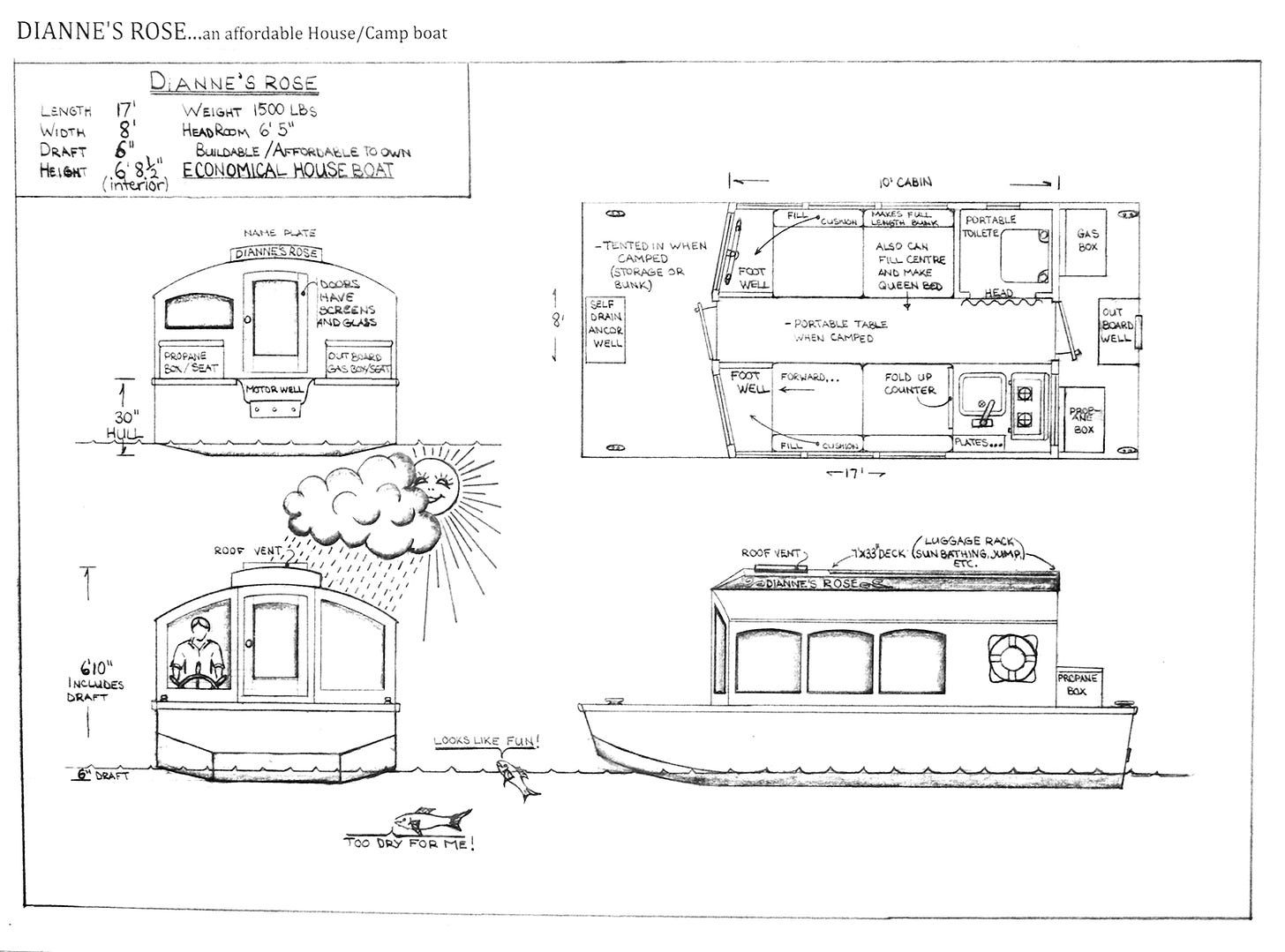

The boat I’ve been building has come out of the shed for some air. It still needs finishing touches but they’ll come over the winter and early spring. Now resembling the drawings I sketched a while back, I’m excited to see it standing in front of me in 3D and thought I might show it to you and see what you think. I’ve named it Dianne’s Rose for my wife. A good sport, she often joined me on outings in my beach cruising sailboat but never fully warmed up to the “tippy” boat. One day she commented that she would come out more often if we had a more comfortable boat. Because I like my wife I decided to stop sketching small sailboats (one I even started to build) and instead draw a small houseboat we could both appreciate.

I’ve never cared for many of today’s fiberglass offerings and have some different ideals about boat designs, so to build from scratch seemed the right choice for me.

I’ve never cared for many of today’s fiberglass offerings and have some different ideals about boat designs, so to build from scratch seemed the right choice for me. In designing this boat I factored in:

• Dianne’s wish to be comfortable. My experience on our beach cruiser, namely its ability to cruise in shallows.

• Our finances—so it should be affordable to build and own, a wish to have a boat that was visually pleasing, practical and safe, and my hope to make it amateur builder friendly so if reviews are good, I will be able to offer plans.

• My belief that bigger is not better.

For my wife’s 50th friends and I arranged a surprise vacation aboard a 42-foot houseboat. It was a great success—especially seeing Di’s excitement. Since I’m building a houseboat it added to my hope for a bright boating future that includes her participation. As a bonus I found a teak steering wheel in an antique shop that might have belonged to a hoarder except I could not dispute the value of her collection. At a reasonable $65 it will match my sketch and give the boat I’m building a “yacht” feel. Perfect!

That said, my wife and I agreed a boat this large cost too much to be sustainable. If we owned such a boat it would become a burden, with monthly payments, dockage paid by the foot, gas and maintenance (we were warned a new prop would cost us $300) and storage. I think it would also become boring as the view coming and going from homeport would become repetitive. There’s safety in size, yet when the wind picked up we had to pass several safe coves because our draft did not allow entry. Going smaller can be safe, saves money, and with the addition of a trailer, a new lake or river is always in reach, so boredom won’t be a problem.

The main issue to overcome in this smaller houseboat is comfort. Comfort being a big point on Dianne’s wish list, I did not omit any of her priorities. What I needed to do was make each area in our boat flexible, having several uses. The boat is 17-feet long with an eight-foot beam. This is the minimum size I felt I needed to meet our requirements (minimum because I wanted to keep it affordable, wanted the ability to explore shallow areas, and wanted to have the option of trailering.)

The bow resembles that of a scow, square and is also necessary to add living and deck space. Not everyone will like this look but if I can get them inside to see the space created and push my luck a bit further and get them out on the water to see the performance, they will change their minds having experienced the advantages of this shape!

This boat is also flexible enough to be used as a camper, possibly saving another expense. To keep things simple I’m using camping equipment whenever practical and with hand-held electronics (GPS etc.) where possible. When viewing the plan, note the 10-foot by 8-foot cabin with a clear passage from bow to stern allowing entry from the 4-foot by 8-foot front deck, and exiting out to the rear deck without obstruction. Di wanted to be able to move about easily and the eight-foot beam also assures stability (not “tippy”), while still being legal to tow on all roads. Gas and propane are left outside on the rear deck (storage boxed to come) for safety. A 9.9HP long shaft on the transom is my preferred method of power (fuel efficient, light weight, no registration required, my household insurance covers this, and minimum maintenance) and can be reached from inside the cabin for easy inspection.

To the left, rear (inside the cabin) is a minimal but comfortable washroom (head) with good sitting and standing room. The portable toilet can be pushed back under the rear deck to make a change room for getting in and out of swimwear. Hooks on the wall make it a closet. Hands will be washed at the kitchen sink and gray water will be collected in portable jerry cans and disposed of on shore. The head will have a curtain for privacy, beach towels with button holes sewed into the corners placed on hooks, here they can also dry. They can be arranged for privacy, to expand the kitchenette and head area, creating a functional private bathing area. As mentioned, systems are simple so a camp shower placed on a shelf, hot water from a kettle heated on the propane stove or portable wood stove (I’m intrigued with the idea of collecting and filtering hot water from the engine when running in fresh water), with shower curtain enclosing a basin (doubles as storage bin) placed on the floor. This will feel luxurious at the end of the day. The kitchenette has a 6-foot counter with a propane camp stove and sink (water to be hand or foot pumped). Storage below is plentiful and is hidden by tea towels with buttonholes, and shelving above will come for dishes.

A cooler (12v powered with a solar panel?) can fit mostly under the deck in the aisle. On hot days the rear door can be opened expanding the kitchen and cooking can be done there keeping the heat outside.

Moving forward, 62-inch couches on both sides face one another with storage below and behind, and double as single bunks. Fillers at the ends (used if our son is coming along and he can sleep on an air mattress in the 28" aisle), or becomes a queen sized bed when filler boards are positioned in the middle and cushions put in place.

Sitting at the forward end of these couches using stadium chairs, they become the simple captains chairs when piloting (captains because I’m never fully in charge). For dining the filler boards will also become a folding table and two benches for added seats, this will allow us to dine as many a six in a 17-foot boat. The benches also serve as the steps to enter and exit from decks. The set can also be put on the front deck to dine two outside or on the shore.

There will be eight large tinted Lexan windows for a good view, not including the doors that will lock. The six side windows are fixed. Two large roof vents are also our skylights. There are two opening bronze ports friends got me for my 50th. Thank you! These and a rear-opening window will add to an airy feel contributing again to comfort (screens on everything of course).

Also storage in bins organized under the bow will minimize clutter in the living space. I’m planning a covering for the forward deck that will create extra sleeping space similar to what pop-up campers have, and I will get to the hardwood floors, 3/8in., (I have some Ash from a fallen tree I had milled but marine ply could be used). This is structural. It backs up the center joint along the cockpit sole and thickens the middle of the hull to one inch. This and the four one-inch ash runners that are clad in aluminum on the bottom will allow for the beaching, bumping and other abuse I plan to dish out. If I can just behave myself Di’s comfort is assured.

Construction is a combination of stitch and glue and framed marine ply sheathed in fiberglass and is straightforward. A quick note on wood construction: My beach cruiser’s hull is solid cedar with ply decks and is 57-years old. I have a friend who is in the middle of rebuilding a 20-year-old fiberglass boat because all the structural parts have rotted. Many glass boats also rely on wood for their structure. There is no reason wooden boats can’t last as long or longer.

I recommend marine grade plywood and rot resistant material below the waterline, but above, regular construction grade lumber could meet your goals and cut costs dramatically. An example of where I saved was the ceiling. It’s old T&G pine salvaged from a torn-down cottage.

Two main frames run fore and aft and serve as strong backs during construction. These become the couches’ fronts or aisle’s sides. For safety and strength they divide the hull into three separate 16-inch high compartments. The sides are further divided by three crosswise bulkheads. All three compartments have a forward and aft bulkhead that crosses the whole width of the boat and “egg-cartons” the two main frames together.

With the bow and stern attached, the two ½" 4x8 bottom panels can be fitted keeping everything square. Then the sides can be hung. It is a simple matter of attaching the “side/bottom” panels and the hull is basically ready for glass. The hull produced is flat across the middle in profile, four feet and “V”s up on the 23-inch sides five inches. In length it curves up and out of the way of waves at the bow or forward four feet, and is a straight run to the rear—a simple shape and one that offers very shallow draft but a reasonable ride.

In my opinion deep “V” hulls tend to rock too easily and need enough depth at anchor that it becomes difficult to find shelter. So the boat is more exposed to the waves, which adds to the discomfort. Our shallow draft expands options to find shelter, both a safety and comfort point.

I should mention, while a wood boat should float, I plan to add 1.5 inches of foam board for added flotation and insulation.

Of course there was a little more to the construction of the hull than mentioned here, but each step is within reach of someone with basic carpentry skills and I have taken many pictures and written descriptions.

The cabin with the curved roof is intimidating at a glance but the roof is divided into three sections, each with a small curve so no laminating or bending is required. A simple pattern eliminates the thinking. These curves, besides giving the boat it’s “look” are intended to put the height where needed while keeping windage down. The remainder of the cabin is approached in similar fashion as the hull. I still have decisions to make: should I canvas the roof or fiberglass? Paint or varnish? We’ll see, and you can too when I launch next spring. •SCA•

Email royschreyer@gmail.com. Full plans available.

[First published in May/Jun 2013 SCA issue #81]

What a fascinating project. Would love to see the finished boat and stories of your adventures in it. What changes have been made from experience ? Do you use it as a trailer camper ? More please.

You can find more info on this fine boat on Shanty Boats and living lazy on the water. It's a FB group. I think another one is Home built house boats/Shanty boats. Also a gentleman built Jersey Girl, a slightly lengthened Diana's Rose.