We received a letter from sailor Bill McConochie, who wrote about a leaky centerboard and possible rot in his Glen-L 19 sailboat’s trunk area. He’s tried a few quick fixes with poor results. We thought we’d share his note with readers in case you all have some ideas or suggestions for him. He wrote:

There was some leaking when I put the boat in recently that suggests the “gasket” I used (rubber designed to seal a garage door at the floor when closed) may not be reasonable. Perhaps there’s another gasket material, such as a floor pad made of rubber that I could fit to cover the whole centerboard trunk with no openings? I'm curious what others have used for this gasket task.

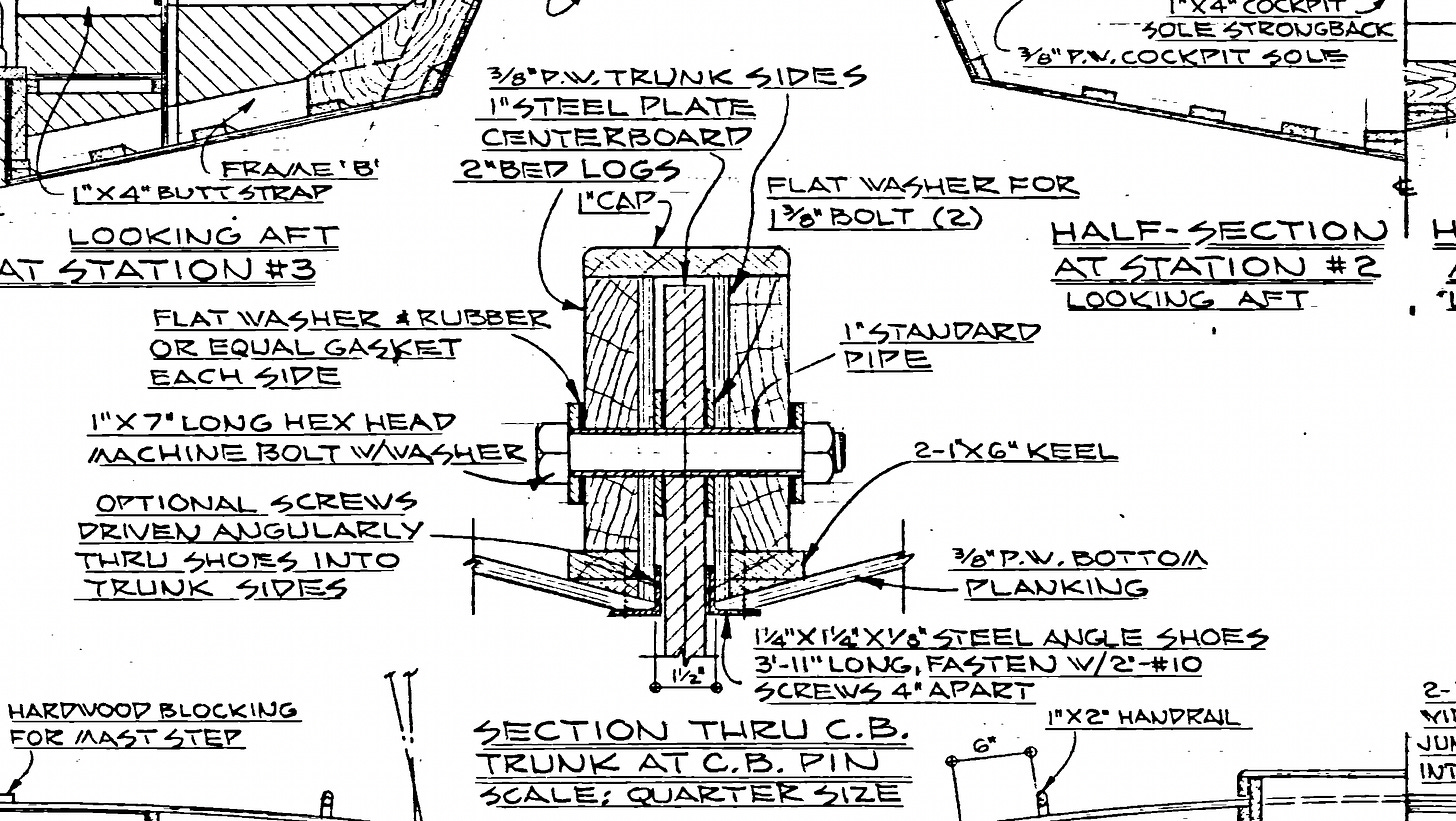

I believe the main problem has been a leak between the pipe that is inserted through both sides of the centerboard trunk and the centerboard itself. I think the hole that is drilled through the 2 1/2-inch side on both sides must somehow be carefully and completely sealed with epoxy before the pipe that houses the main bolt is inserted. And that this pipe must fit smoothly and with another watertight coat of some sort before it is installed, and that the final bolt that holds the washers does so very snugly with rubber then steel washers to prevent leaks.

I realize that my memory of these pipes is somewhat vague after 40 years, so I'm open to comments on this point. But water definitely was flowing into the boat through the joint of the washers and nut on the starboard side of the trunk but not the port side.

During the past several months I injected a liquid designed to harden defective wood. I used a 3/8 inch bit about 16 inches long and inserted it from the top of the centerboard trunk on both sides. I filled the holes with epoxy resin after the initial liquid insertions solidified. I used a rubber seal around the top of the box and then screwed down the cap. I put the boat into a local reservoir a week ago with the help of a semi-retired carpenter who was on the site and volunteered his assistance. It went well, but there were leaks. The main leak was on the starboard side of the trunk where the nut secures the metal and rubber washers to the side of the trunk, where, I suspect, the main leak has been over several decades.

I realize that I will die someday having spent 20 times the hours in building and maintaining the Artful Dodger than in sailing him. But he's a delightful fellow who has pleased our family and many friends over the years and I'd love to leave him some day to other sail enthusiasts to use ad infinitum. We sail on Fern Ridge, a reservoir west of Eugene, where we live. I'll be interested in any advice. Photos below.

Readers: Do you have your own maintenance or repair dilemma? Feel free to send it to us with details and we might share it with our readers for feedback. Send to josh@smallcraftadvisor.com

•SCA•

Looking at the 5th photo from the top, it appears to me that the side of the CB trunk is bowed out a little, which indicates (to my inexperienced eyes) that you have a water infiltration problem in the plywood and need to bite the bullet and rebuild it. But it may be just my eyes, as with my latest glasses my round frying pan suddenly appears oval....

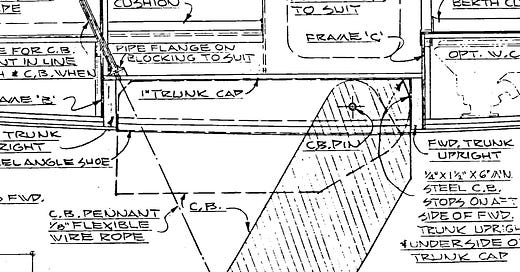

I'm concerned that over tightening the CB bolt will squeeze in the trunk sides, so you will not be able to stop the leak that way. One way I have done this is to start with a pipe flange on each side of the trunk. This can be screwed down, with plenty of bedding compound under it (My preference is for Dolphinite). Of course you would use brass or bronze here. I see you have only 3/8" sides on the trunk, so you would have to use short screws. Could be reenforced by drilling 4 more screw holes, giving you 8 for each flange. These could be countersunk for FH screws, or just use round head screws.

Into each pipe flange, screw in a short nipple, threaded both ends. Use pipe compound to prevent leaks through the pipe fittings. Insert your centerboard bolt, then screw on pipe caps to the ends of the pipe nipples. Should take care of your leaks. Only problem is avoiding stubbed toes with these protuberances. The CB bolt can be free floating; no need for it to be a tight fit.